References

We have been in business since 2003. We have experience with structural funds in four EU budget periods at national and international programme level. We work with small and medium-sized enterprises and corporations. We adapt to the current needs and requirements of our clients.

We have helped realise hundreds of projects in industry, business and regional development. We have selected the most interesting ones for you here.

Photovoltaic power plant with hydrogen energy storage

Construction of a new renewable hydrogen production plant for the decarbonisation of the chemical industry and transport in the Ústí nad Labem Region. The production plant will consist of a renewable energy source - a photovoltaic power plant with an installed capacity of 60 MW, supplemented by hydrogen electricity storage technology with a capacity of 28.9 MWh.

Flue gas heat recovery in Kralupy refinery

The project concerns the use of waste heat from the flue gas at the Kralupy refinery to produce feedwater for the fluid catalytic cracking (FCC) unit. The use of flue gas heat will be made possible by the use of special plastic heat exchangers that allow the flue gas to cool below its dew point, when condensation of sulphuric acid occurs, to which the plastic heat exchangers are resistant and therefore not subject to corrosion or other destruction of the equipment.

Advanced (chemical) recycling of plastics

The subject of the project is the selection, construction and operation of the technology of so-called licensed suppliers for the chemical industry using anaerobic thermal splitting to convert mixed waste plastics primarily into liquid intermediates to be used as raw material for the production of petrochemical products using ethylene unit or other so-called petrochemical units.

Energy recovery from wastewater heat

Energy recovery of waste heat from wastewater with the installation of a water-to-water heat pump and implementation of other related measures in the mixing of alkalinised inorganic and biological waters, pumping of wastewater, its inflow and flow and technological optimisation of the activation and sedimentation process contributing to ensuring the year-round energy potential of treated wastewater.

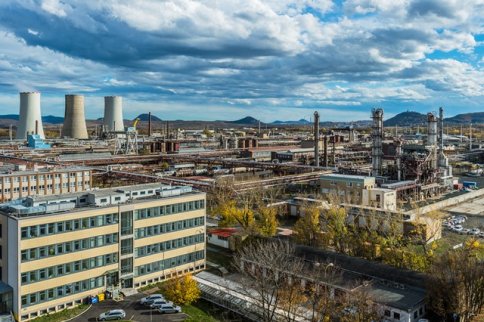

Innovation and expansion of CHA/DCHA production at Borsodchem OH

Implementation of a new 60ktpy CHA production unit meeting strict ecological and safety limits, consumption and energy standards. Renewal of the existing DCHA technology in the existing CHA unit to a production capacity of 10ktpy, i.e. implementation of technology meeting strict ecological and safety limits, consumption and energy standards.

Replacement of the RT extractor with a vertical tower type extractor

Replacement of two horizontal extractors RT93 and RT96 with one tower extractor (vertical type). The production capacity (10,000 t of beet/24 h) will be maintained.

The operation of the extractors consumes electricity to drive the extractor and heat to evaporate the water from the juice. The new tower extractor makes it possible to reduce the amount of water that has to be evaporated from the juice. This reduces energy consumption and emissions.

Gasification of the Ceske Mezirici Sugar Factory Coal Plant

Replacement of four existing coal-fired boilers with gas-fired boilers. The advantages of the new technology are low emissions of pollutants from the combustion process compared to coal combustion, higher thermal efficiency of the boilers and the boiler room as a whole, reliable operation and automation of the boiler room equipment.

Kamenolomy ČR - Lhota Rapotina - snižování prachových emisí

Technological measures aimed at reducing dust generated by working activities in the quarry. The existing line is equipped with a dedusting system, but still emits a significant amount of emissions into the surroundings of the plant.

Modernizace procesu výpalu slínku v Cementárně Mokrá

Reducing CO2 emissions and achieving energy savings by modernising the clinker firing plant in Mokrá. Specifically, it involves replacing two clinker production lines with one modern, more energy-efficient one. Integral to the project is the installation of a new heat exchanger with calciner, a new clinker cooler, a new raw material mill with VRM, homosilo, connection to existing equipment and the transport of alternative fuels with a lower CO2 emission factor (TAP / RDF LG) to the new kiln line.

Green hydrogen

Construction of a photovoltaic power plant, a wind park and an electrolyser with the aim of producing green hydrogen and implementing it in ammonia production. The implementation of the project has a positive impact on the reduction of CO2 emissions and the energy intensity of production

Gas boiler house for production of low pressure saturated steam - sugar factory Opava

The gas boiler plant will replace the existing steam boiler plant, which has four grate steam boilers installed. Boilers K1, K2 and K3 use a combination of coal and biomass as fuel during the campaign period.

Reconstruction of heat distribution, Reconstruction of heat exchanger station

Modernisation and merging of two existing heat exchanger stations of hot water heating sources into one, optimisation of production capacities and reduction of the scale of internal steam pipes of the heating plant.

Stora Enso Wood Products Ždírec s.r.o

The aim of the project was to introduce combined heat and power production in the industrial premises of Stora Enso Wood Products Ždírec s.r.o. located in Ždírc nad Doubravou.

The company is engaged in wood processing, which generates a large amount of wood residues from production, the so-called biomass. The creation of its own heat source offers the possibility of efficient use of wood biomass for heat and electricity production.

Reduction in SOx Emissions at the Mělník I Power Plant

The project’s aim is to build a new, completely desulphurised facility at the Mělník I Power Plant using the wet limestone process, including ensuring, using or rendering harmless all products and waste that arise during the waste desulphurisation process.

Research and Development of an Active Antenna System to Detect Objects of Interest with Support for Measuring Polarimetric Properties

The project’s aim is research and development of an active radar antenna system for measuring the polarimetric properties of objects of interest, which include, for example, vehicles, people, drones, and more.

Research and development of EDA tools and multi-core application processors with RISC-V accelerators

Research and development of a new generation of EDA tools and processors based on RISC-V architecture and their first industrial deployment. The development of a new RISC-V processor architecture responds to new applications such as artificial intelligence and machine learning, cybersecurity, and computer vision.

Modernisation of Tyršovo nábřeží hot water pipeline in Zlín

The project’s aim is to modernise and optimise the existing heat supply network, including transfer stations, with the aim of achieving maximum primary energy savings. The project is focused on the replacement of part of the existing hot water pipeline dating from the 1950s with a new hot water pipeline on the route of the current hot water pipeline at Tyršovo nábřeží in Zlín.

Research and development of configurable embedded RISC V processors

Research and development of a completely new design solution for embedded RISC-V processors in two performance variants determined by different combinations of basic processor parameters (power consumption, area on chip, speed, performance). These processors will be targeted at manufacturers and users in current areas of technological development such as artificial intelligence and machine learning, cybersecurity and computer vision technologies.

Reducing the energy consumption of the Podkonice municipal office building

Building modifications that will contribute to promoting the energy efficiency of the building.

TR Kočín - Expansion, Refurbishment, Alteration to Lines

The aim of the Expansion and Refurbishment of Kočín Substation project is to strengthen the energy security of the transmission grid. The implementation of this project will contribute to improving the quality, safety and sustainability of electricity supplies to end customers. It will also enable the development of industry and business in the relevant locations.

Tertiary reduction system KD2 in Duslo a.s.

Electrification of the railway siding Litvínov

Complete implementation of the extension of the 3kVdc overhead line in the perimeter of the St8 substation

and partly also the St5 substation. This includes complete track reinforcement

of the transfer station "ORLEN Unipetrol RPA, Litvínov" at the railway junction

between the Litvínov siding and the SŽ line, in total over 9 tracks.

Construction of a new kindergarten in Trnava - Mateřská škola Prúdy

Construction of a new kindergarten in Trnava to support capacity expansion.

Multigenerational rope centre on the Bata Canal, port of Veselí nad Moravou

Expansion of the accompanying infrastructure for visitors in the area of the port of Veselí nad Moravou on the Bata Canal, in the form of construction of a multi-generational rope centre - a 3D maze with a lighthouse tower and a children's playground.

Modernisation of nitric acid production

Energy savings and reduction of CO2 emissions. Complete reconstruction of nitric acid production, where the existing lines KD6, KD7 and KD8 will be closed and replaced by a new modern line KD9.

Modernisation and energy efficiency improvement of the municipal office building

Complete reconstruction of the municipal office building in the village of Priechod.

Innovative Leather Processing at KARO – Leather Company s.r.o. - Brtnice Branch

The project’s aim is the introduction of a fully automatic operation for processing leather that meets Industry 4.0 conditions together with an overall reduction in the environmental burden from production while maintaining the required qualitative and economic parameters.

Research and development of complex technology for production of stable semi-finished bullet products - phase A

Research and development of a complex technology, which will consist of two basic parts: rolling of perfect brass strip with a new system of cooling and lubrication of rolls for subsequent volume forming of stable hub blanks, so-called cups, and pressing of cups, whose dimensional properties will be significantly improved and stable.

Research and development of complex technology for production of stable semi-finished bullet products - phase B

Research and development of a complex technology, which will consist of two basic parts: rolling of perfect brass strip with a new system of cooling and lubrication of rolls for subsequent volume forming of stable hub blanks, so-called cups, and pressing of cups, whose dimensional properties will be significantly improved and stable.

Research and Development of a Multipurpose Vehicle Platform with Four Electric Motors and a Control System

The project’s aim is research and development of a multipurpose vehicle platform with an electric drive.

Innovation and Expansion of CHA/DCHA Production at BorsodChem

The project’s aim is to start the production of innovated cyclohexylamine (CHA) and di-cyclohexylamine (DCHA) products, and the related innovation of their production process.

Research and Development of a Continuously Variable Transmission for Use in Trucks

The project’s aim is research and development of a continuously variable transmission with a proprietary design that can be built in to trucks for various types of uses (fire, goods, rescue, with special superstructure, municipal, forestry and agricultural, military, etc.).